The healthcare sector is all about trust. Patients entrust their lives to doctors who rely on quality medical equipment. Whether it is surgical equipment or diagnostic equipment, all products must be of the highest standards of accuracy and safety. This is not just the responsibility of manufacturers but also the entire supply chain.

This is why quality processes are so important. They ensure that all the devices that go to the market work as they are supposed to. In a business where a small defect could mean life-altering consequences, there is no such thing as being overly cautious.

Why Medical Devices Demand Rigorous Oversight

Medical devices are not like most other consumer goods. When your phone breaks down, it is annoying. However, when a pacemaker or insulin pump or an imaging scanner breaks, the consequences may be fatal. This is why regulations on the international level are very strict in terms of safety and reliability.

The process of oversight begins well before gadgets get to shelves. Individual parts are tested, materials are scrutinized, and production is carefully watched. Without such a structure, even minor mistakes could pass through, and eventually, this would affect the health of patients. Oversight, then, is impossible, but necessary.

The Core of Quality Control for Medical Devices

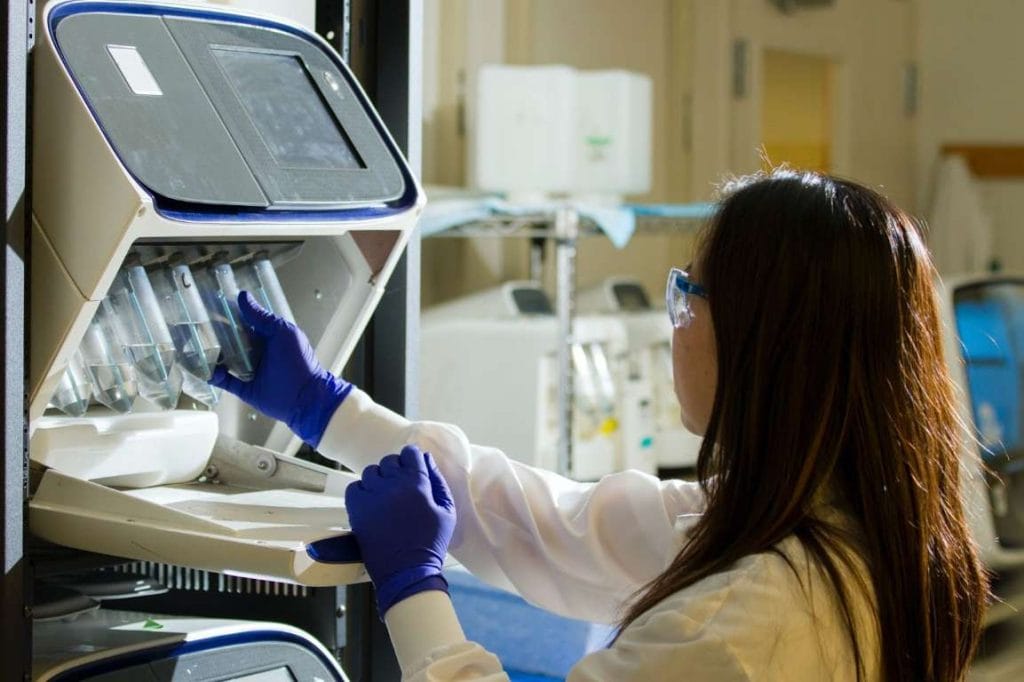

Quality control in the manufacture of medical devices is at the core of the manufacture where safety is embedded in the process. It is not just about the end product, but rather quality is built into design, production and post-market processes. Specialists and engineers inspect prototypes, materials and production lines, preventing the occurrence of problems at later stages.

This stratified method implies continual checking. Every batch is tested to very specific specifications during manufacturing. Devices are tested in real-life environments to ensure that they perform similarly before they are shipped. Monitoring is further continued after launch to detect risks that may only manifest themselves after prolonged use. Collectively, these actions form a loop of trust.

The Role of Supplier Audit

Supplier Audit is important here. Medical device manufacturers seldom make all of their own parts. Instead, they use international suppliers of materials, electronics, or even partially assembled components. That reliance makes supplier performance a direct indication of the overall product quality.

- Process Verification: Audits test whether suppliers adhere to the correct manufacturing practices that are in tandem with regulatory requirements.

- Material Consistency: The raw materials should be tested to establish durability, safety, and compliance. A poor material may invalidate the whole device

- Documentation Review: Documentation is verified to guarantee visibility and traceability through production batches.

- Corrective Actions: In case gaps are noted, then the suppliers should correct the gaps in time to prevent the risks downstream.

A deep audit assists companies to establish better relationships as well as maintaining compliance. It is a safeguard and a confidence-building step with global stakeholders.

Common Challenges in Medical Device Quality

The management of quality across several suppliers presents new challenges. Components can be bought in various countries, and the differences in regulations and standards might lead to inconsistencies. A supplier who passes checks in one region may not be up to the mark in another. This presents an additional challenge to international manufacturers.

Added to that, the fast-paced development of medical devices presents its own challenges. Devices are becoming smarter, connected, and software-driven, so the audits and quality checks will have to increase to include cybersecurity and software validation. This has to be balanced against cost pressures, which makes it even harder to ensure perfect quality.

Why This Matters More Than Ever

There is growing demand in medical devices across the world. As the population ages and healthcare technologies improve, millions more people are depending on these devices every day. Those dependencies imply that errors are more expensive than ever before. This is not only about regulatory penalties, but also about protecting lives.

This increases the importance of supplier relationships even further. A robust audit mechanism will make all the players in the supply chain responsible. By being consistent across borders, manufacturers can be able to conform to international standards, as well as provide assurance to both patients and doctors.

Conclusion

Patient health does not only mean great devices. It is about developing an ecosystem where all elements, all processes and all suppliers are focused on the same objective: safety. By adding Quality control of medical devices to comprehensive Supplier Audit, companies can achieve compliance and gain international confidence.

Ultimately, global standards are not mere paperwork. They are the spine of patient safety and credibility in the industry. In a world where lives are at the mercy of technology, nothing short of maintaining standards is essential.